A Better Look at What’s Makes Today’s Sophisticated Embedded Storage Chips That Help Mobile & Small Footprint Devices Create a Digital Revolution

Mobility could be the defining term for technology in the 21st Century—and that mobility is enabled by innovations in producing the mobile chips that enable smartphones, ultrathin laptops, tablets, automotive and many smart industrial products.

BIWIN’s BGA SSD EP400 is an example of an ultra-small storage chip taking giant steps via advanced technologies to enable mobile and small footprint devices.

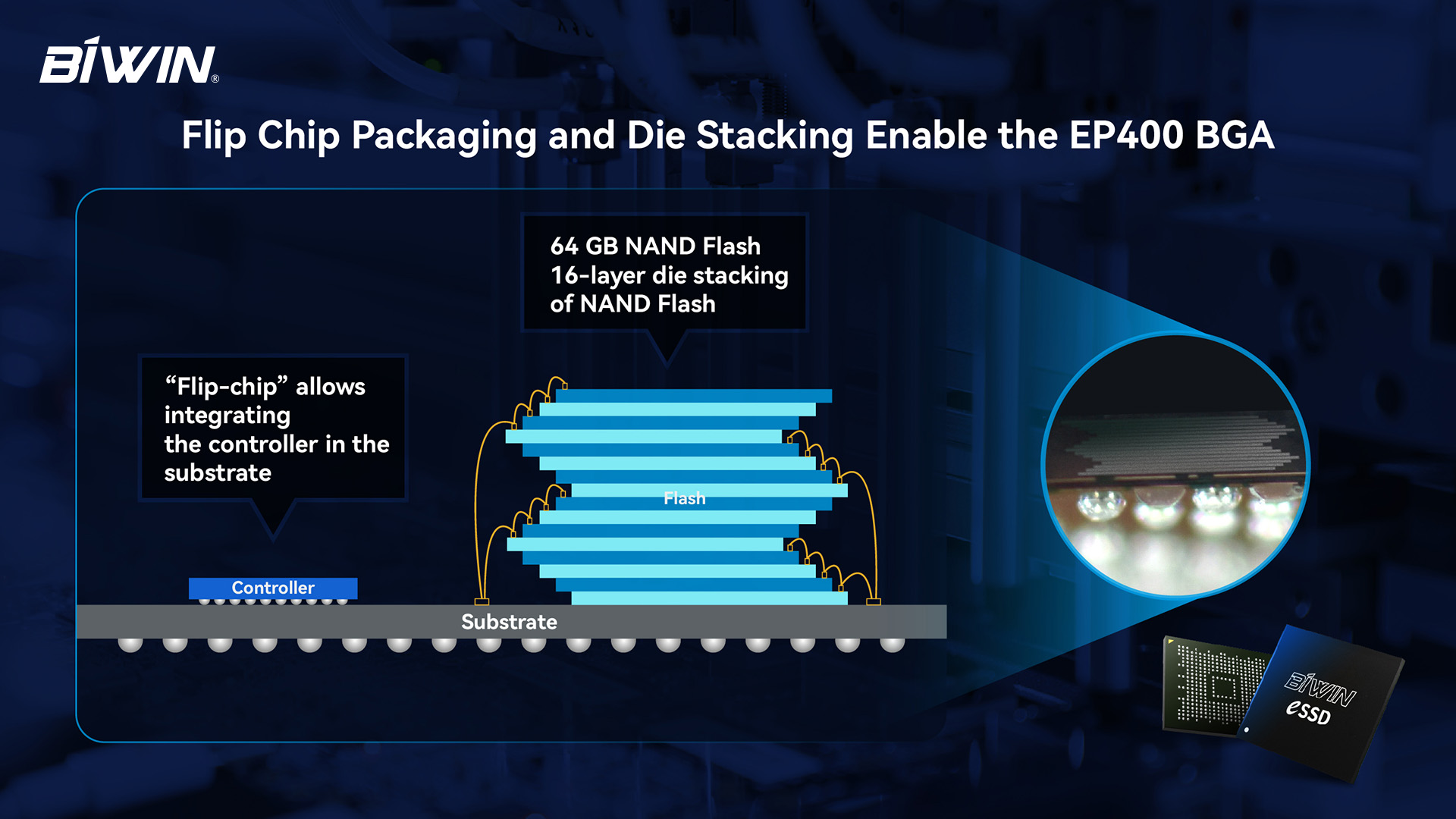

The capacity of a single NAND flash die used in the EP400 is 64 GB. Through advanced packaging processes such as 40 μm ultra-thin die and 16-layer die, BIWIN can produce a package thickness of only 1.5 mm--and yet the finished chip storage capacity can reach 1 TB. (The same process, if we use 128 GB NAND flash, can reach 2 TB.)

BIWIN’s expertise in chip packaging is important because IC packaging is the critical link in the integrated circuit industry, the bridge between IC and external systems. Packaging protects the IC from corrosion or physical damage, but it also makes it easier to connect the IC to the printed circuit board (PCB). IC packaging handles wireless communication and signal processing while considering the product’s performance, reliability and heat dissipation.

BIWIN EP400 adopts novel flip-chip packaging to provide a small size die, faster data transmission, and higher signal density. Featuring a crystal oscillator module built-in through the packaging process, EP400 integrates more functions, reduces the required integration area, and simplifies the design complexity of board-level peripheral circuits. All this further improves product performance and adds more reliability.

Advanced technology in chip production does require a more advanced quality control process. Along their way in the packaging and production process, BIWIN BGA SSDs must pass strict tests including an electrical test, SI test, application test, compatibility test, and reliability test. Providing a MTBF of 1,500,000 hours, EP400 proves to be very stable and resistant to even 1500 G (Gravity) and 20 - 2,000 Hz vibrations.

The big challenge facing storage testing is the ability to analyze storage media, to understand potential failure modes and to develop underlying algorithms for software, hardware, and equipment. With the upgrading of NAND and DRAM technology, IC testing will lead to the improvement of related technologies as well as equipment.

In response to the challenges of using increasingly advanced technologies, BIWIN had to build its own strict quality management system covering the entire product life cycle.

When advanced technology is required, even the small storage chips require a huge investment in packaging and production quality control. This investment may be mainly unseen by the device users, but it proves that while “good things come in small packages,’ you need a large experience in packaging and production to bring the mobile revolution in computing.

With its new facility in Huizhou, the 110,000 sq. meter BIWIN SCIENCE & TECHNOLOGY CAMPUS, BIWIN now looks to lead the industry in key quality indicators such as test case coverage, product delivery efficiency, and product yield.