Amid the ongoing evolution of urban transportation, the landscape of in-vehicle products, such as dashcams, GPS vehicle terminals, and in-vehicle entertainment systems, is undergoing a notable transformation. These products are no longer limited to collecting basic driving information, GPS location data, or image capturing alone. The contemporary demand extends to real-time video recording for comprehensive scene reconstruction. Simultaneously, the precise gathering of various vehicle signals is a dependable data source for evaluating driver behavior, monitoring passenger loads, and assessing vehicle operational statuses. This growing emphasis on in-vehicle surveillance underscores its increasing significance in our evolving urban environments.

Among these components, in-vehicle storage hard drives are becoming increasingly crucial as the core elements responsible for data storage and transmission in the evolving in-vehicle surveillance market. With the emergence of new challenges and opportunities in the storage market presented by automotive electronics and rail transportation, BIWIN has introduced a comprehensive range of in-vehicle storage products, including SSD, BGA SSD, DDR, UFS, Micro SD card, and more.

In this issue, we will place a special focus on BIWIN’s solutions for in-vehicle surveillance equipment and data-intensive applications like safety monitoring in rail transportation. We will delve deep into the pain points that the industry is currently grappling with and provide a multifaceted exploration of the characteristics of in-vehicle surveillance storage applications.

Challenge 1

How to Solve Mass Data Storage Problems

Today, the development of automobiles parallels that of smartphones, with increasingly complex functionalities integrated into vehicle systems and a corresponding surge in data generation. On one hand, vehicles are equipped with an ever-expanding array of sensors and cameras, continuously collecting, and recording data concerning their surroundings and their status, with the need for longer data retention times, often extending to a month or more for local data storage. On the other hand, introducing features like automotive black boxes has expanded the storage demands of automotive monitoring applications. These functionalities also continuously record and transmit data, necessitating larger storage devices and more efficient storage management solutions.

To address the capacity challenges posed by massive data volumes, let’s take the example of the 2.5" SATA SSD BIWIN C1008. This product offers a range of capacities, including 500 GB, 960 GB, 1.92 TB, and 3.84 TB, effectively meeting the high-capacity storage requirements of in-vehicle surveillance systems. The availability of multiple capacity options also translates to higher compatibility, catering to diverse in-vehicle applications. Currently, BIWIN C1008 SSD is extensively used in areas such as in-vehicle DVRs, security video surveillance, and rail transportation. As the level of automotive intelligence continues to advance, even with the addition of more cameras in vehicles, the 3.84 TB storage capacity can amply fulfill the evolving needs of users in an increasingly intelligent automotive landscape.

Additionally, the BIWIN C1008 is equipped with SATA II interface specifications and is compatible with Serial ATA disk drives, ensuring a seamless integration with in-vehicle monitoring systems. This compatibility enables extended periods of stable data writing performance and guarantees the consistent transmission of video information within the vehicle monitoring setup.

Challenge 2

How to Safeguard Storage Stability in Multi-Route and Long-Term Surveillance

Experiencing interruptions, recording stoppages, or dropped frames in in-vehicle monitoring can undoubtedly be one of the most frustrating issues for users. Ensuring the integrity and reliability of data recording is crucial, especially during continuous, long-term, and high-definition video data writing on multiple channels. This places significant demands on the stability of storage devices.

Take the BIWIN C1008 as an example. In a test involving 12 cameras and 50 cycles of full-disk recording, the product demonstrated a stable, uninterrupted video data writing process with no dropped frames throughout the test. Additionally, the BIWIN C1008 firmware has undergone multiple optimizations, including a garbage data recovery mechanism. It employs a self-developed dynamic load-balancing algorithm that, in a state where there is no write or read activity, proactively organizes, and optimizes the scattered space within the Flash. It also reserves extra blank blocks as a buffer area. This approach enables garbage collection and HOST writing to run in parallel, effectively ensuring the continuous stability of data writing, and greatly enhancing SSD durability and efficiency.

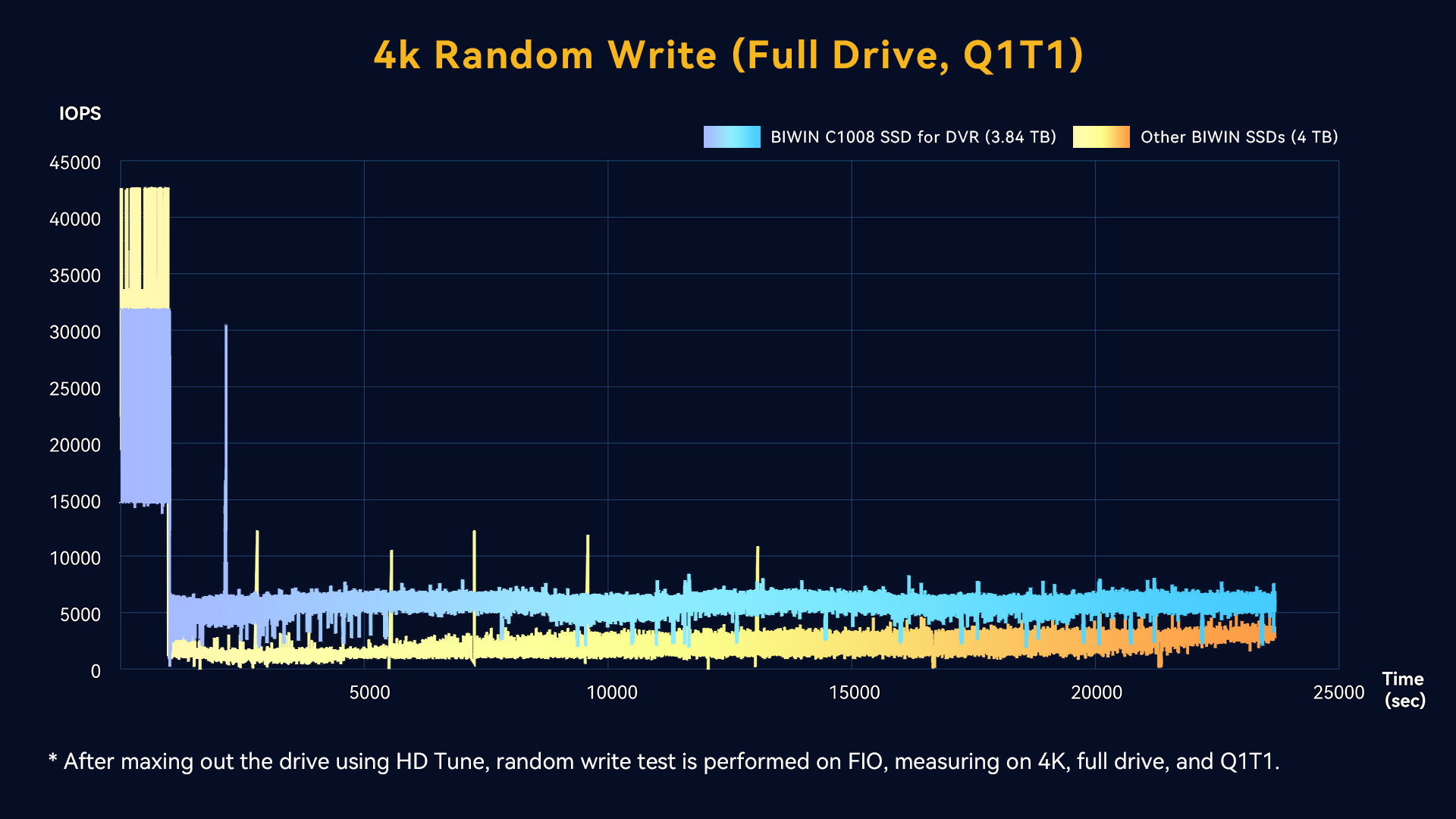

By simulating scenarios where multiple video files are concurrently written after the user’s video files are fully recorded, in a lab experiment involving the C1008, after being fully written using HD Tune, the product (3.84 TB) was subjected to FIO random write tests. In this test, the random write speed remained consistent at approximately 6000 IOPS with no significant drops to Zero. This ensures that even when multiple rounds of video recording take place, the product can reliably capture smooth high-definition videos without frame drops.

Challenge 3

How to Ensure Product Reliability and Longevity in Frequent Read and Write

“Frequent and prolonged read/write” is undoubtedly a major challenge for SSD. To ensure the quality of automobile storage hard drives, the core component, memory chips, plays a crucial role. High-quality flash memory chips can guarantee the storage hard drive's stability, reliability, and durability. Compared to common storage hardware available in the market, the design of the BIWIN C1008 involved rigorous chip selection from the outset, employing 3D TLC NAND Flash with a high write/erase cycle of up to 3000 times.

On the other hand, people can monitor and manage the lifespan of in-vehicle storage hard drives through a series of technical means to ensure reliable data storage and proper system operation. For example, the BIWIN C1008 has an integrated wear-leveling mechanism that evenly distributes data writes across every block of the flash device, preventing excessive erasures in a single block that could lead to drive failure or data loss. The product also comes with S.M.A.R.T., allowing users to obtain drive status information and predict potential drive failures. It also supports firmware upgrades, enhancing the hard drive’s reliability and lifespan.

With stringent chip selection and testing, strong controller support, and the ability for customized firmware development, the BIWIN C1008 product is built to be durable and capable of stable operation even in extreme conditions. Through rigorous and precise testing, the BIWIN C1008 boasts a Mean Time Between Failures (MTBF) of over 1,500,000 hours, ensuring stable and reliable data storage.

Challenge 4

How to Address Abnormal Power Loss

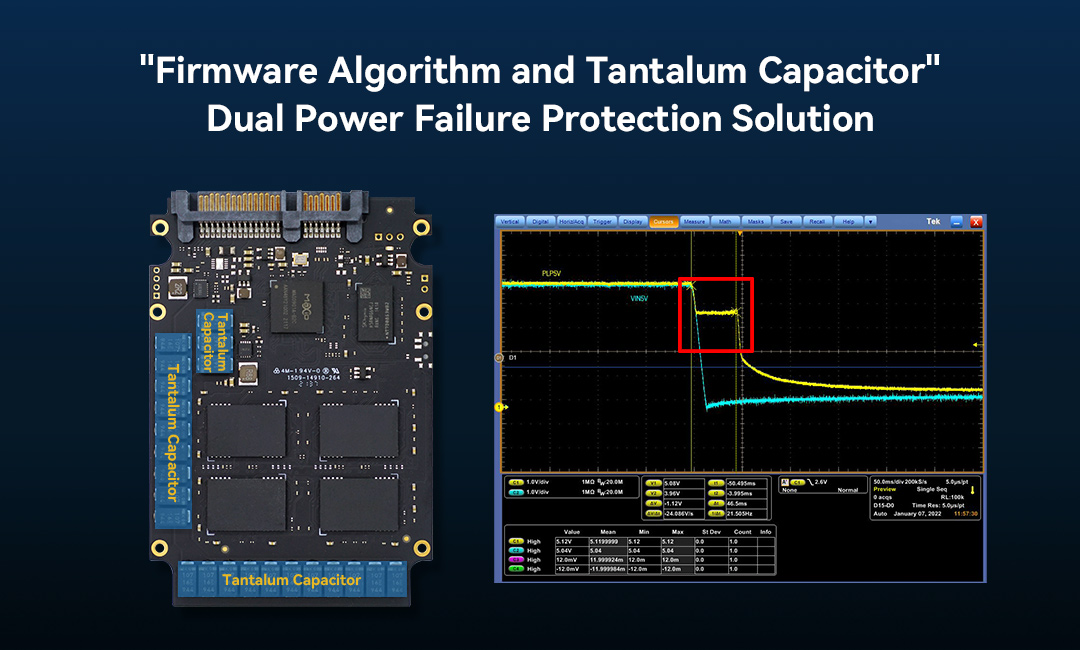

The constantly changing driving environment places automobile storage under complex and demanding operating conditions. Power supply failures or malfunctions occasionally lead to abnormal power loss, resulting in data loss or even complete solid-state drive failure. Therefore, power failure protection for automobile storage is more necessary than for other devices. Modern SSDs are designed with built-in power loss protection mechanisms, mainly at the algorithm level, which means that power loss protection is implemented through firmware algorithms. While this approach does provide a certain level of data security, it still has uncertainties when dealing with extreme conditions.

To tackle this challenge, the BIWIN C1008 implements a dual power failure protection solution known as “firmware algorithms and tantalum capacitors.” This approach ensures that power interruptions at any moment will not lead to data loss or firmware issues. The product includes an integrated power detection chip continuously monitors the power supply status. When any irregularity is detected, it immediately activates the power failure protection module. It utilizes the stored charge in tantalum capacitors to provide continuous power to the SSD during power loss events. This allows dynamic data to be stored in the flash memory, ensuring the safety of firmware programs. Consequently, it guarantees that data loss and firmware issues will not occur in the event of power loss at any time.

Furthermore, through testing and validation of power supply compatibility, dynamic response to power fluctuations, and stability when subjected to varying input voltages, the BIWIN C1008 ensures adaptability to complex power supply environments with voltage fluctuations higher than the conventional 5 V (±5%).

Challenge 5

How to Confront Extreme Environments with Strong Shock and High Temperature

Due to the uncertainties of vehicular environments, which often involve significant vibrations, temperature fluctuations, dust accumulation, and strong interference, ensuring long-term continuous operation of vehicle storage drives requires higher durability, resilience, and heat dissipation capabilities for automobile monitoring storage devices.

The BIWIN C1008 is built with a robust design, starting from the chip level with the application of adhesive reinforcement. The product undergoes impact tests at 1500 G and vibration tests at a maximum frequency of 2000 Hz, achieving a shock resistance level of 6 g. This design prevents chip loosening or soldering issues in high-vibration and high-impact application environments.

Regarding operating temperature, the BIWIN C1008 is designed to support a temperature range from -20 °C to 70 °C. This product maintains stable, reliable, and efficient performance even when exposed to extreme temperature variations, which can result in thermal expansion and contraction, internal electrical changes, and physical property alterations.

Summary

In summary, backed by BIWIN’s expertise in self-developed firmware algorithms and advanced packaging and testing manufacturing processes, the C1008 SSD combines the advantages of large capacity, stable read and write performance, high erase/write endurance, power loss protection, and robust design. It supports long-term stable operation for data-intensive automotive applications and is typically used in areas such as security surveillance, rail transportation, and in-vehicle DVRs.

In the face of new challenges and opportunities brought by automotive electronics and rail transportation to the storage market, BIWIN has made a comprehensive layout from in-vehicle SSDs to automotive-grade eMMC, LPDDR, UFS, and other product series. They continue to introduce storage products that offer higher reliability, stability, and security to provide a variety of choices for in-vehicle applications. In the future, BIWIN will actively invest in research and development and integrated packaging and testing 2.0, continuously customizing industry-grade storage solutions for specific applications to meet the diverse storage needs of customers.