From April 14 to April 16, 2025, the 50th China Electrical Instrument and Meter Industry Development Conference and Exhibition was successfully held in Chongqing. At the event, BIWIN showcased its highly reliable and stable all-scenario solutions tailored for the electric power industry, aiming to support clients in the implementation and production of new-generation power system products.

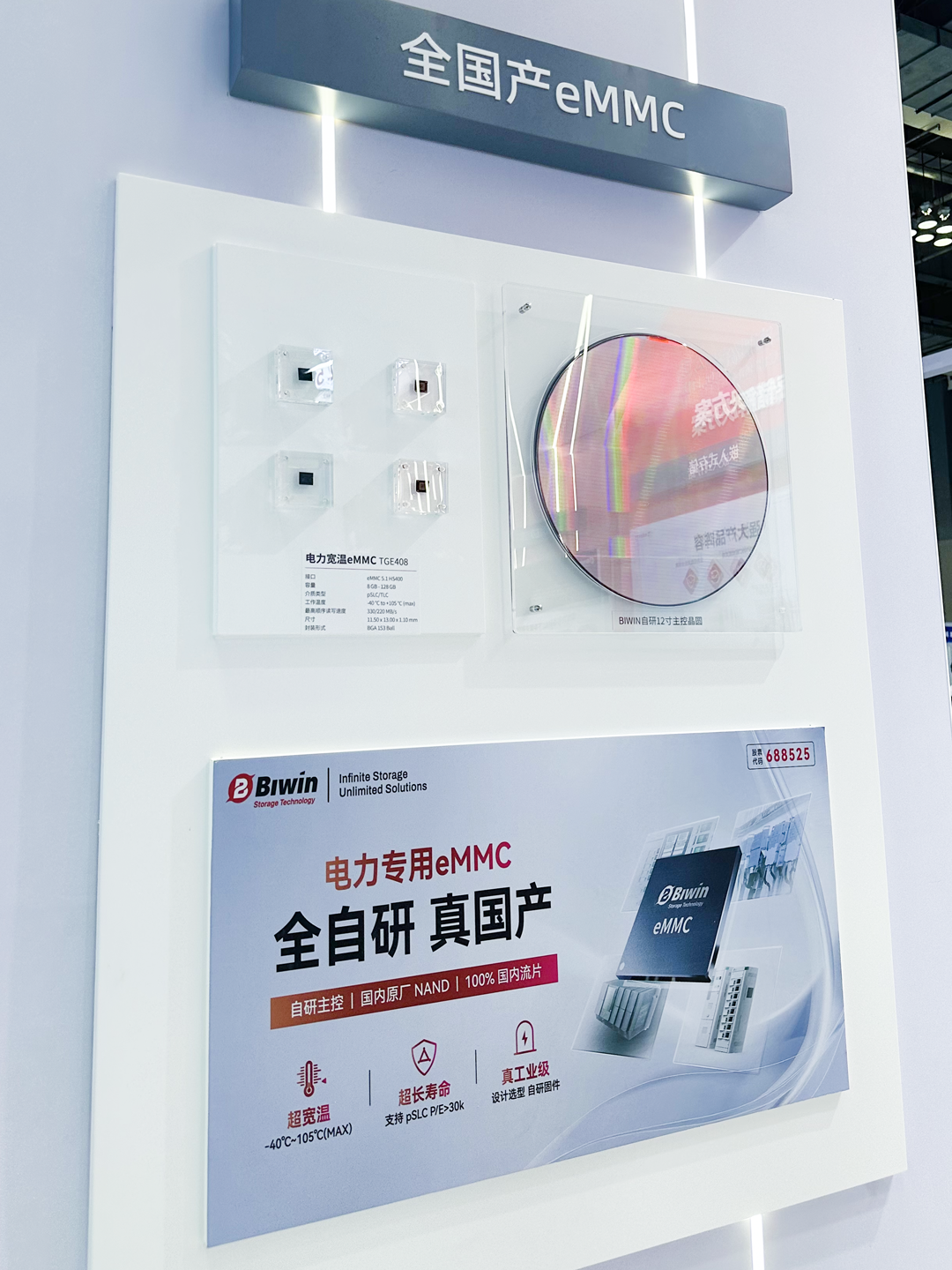

Fully Domestic and Self-Developed Power-Specific eMMC

Customized Stable and Endurable Hardware for Electric Power

The electric power industry has been challenged by extreme temperature fluctuations, electromagnetic interference and more environmental factors throughout the year. The eMMC, characterized by an integrated design, stable performance, low power consumption and shock-resistance, has been widely used in applications that impose strict requirements on data integrity and security, such as data collectors, protection devices, concentrators, and integrated terminals, helping ensure devices’ long-term reliable operations.

The 100% domestic power-specific eMMC, exhibited by BIWIN, comes equipped with BIWIN in-house controller and domestic NAND, realizing full-process domestication from IC design to wafer manufacturing, contributing to the self-reliance and control over critical demands for data security required by the electric power industry.

BIWIN ensures the adherence to electric power industry standards by tailoring its solutions in all aspects from product definition, software and hardware algorithms, testing processes to production and manufacturing. The product series offers flexible capacity options covering 8GB to 128GB, supports wide-temperature operation ranging -40℃ to +105℃, and demonstrates excellent endurance with over 30,000 P/E cycles. Undergone a set of stability and reliability tests, BIWIN’s products are certified with outstanding endurance and environmental adaptability.

The product, featured with BIWIN self-developed firmware algorithms, integrates more innovative technical properties such as low power consumption, power loss protection, wide temperature operation, enhanced data protection and pSLC firmware mode, capable of ensuring zero data loss and uninterrupted storage operations under unexpected conditions like sudden power loss and severe weathers, and extending lifecycle to the largest extent. Designed for electric power devices’ characteristics of high frequency with small data streams, BIWIN’s in-house controller has optimized the compatibility between the protocol and firmware of electric power device, so as to reduce data transmission delays, guarantee real-time write of current fluctuations and fault logs, and prevent the loss of critical data.

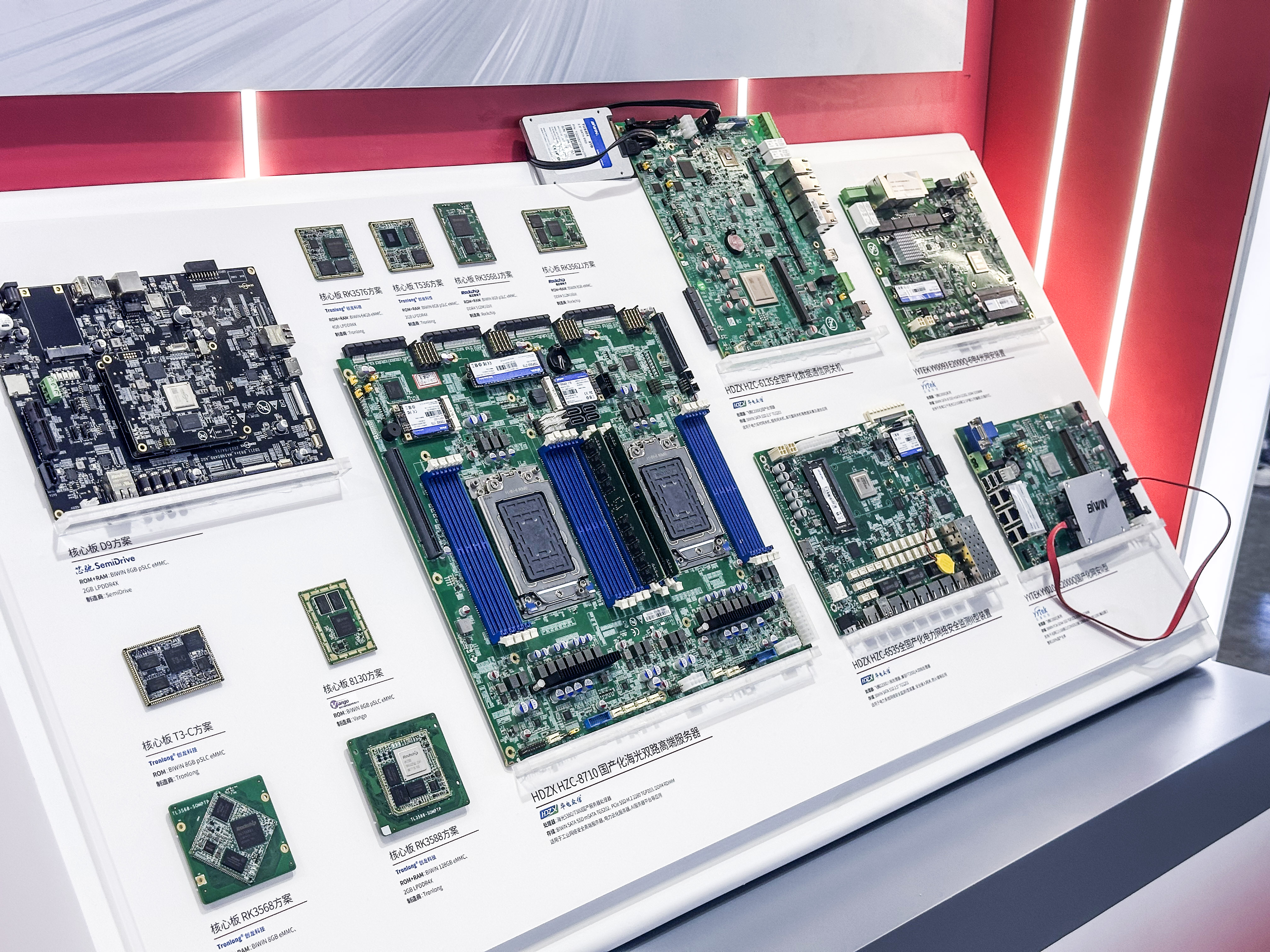

Integrated Solution and Manufacturing

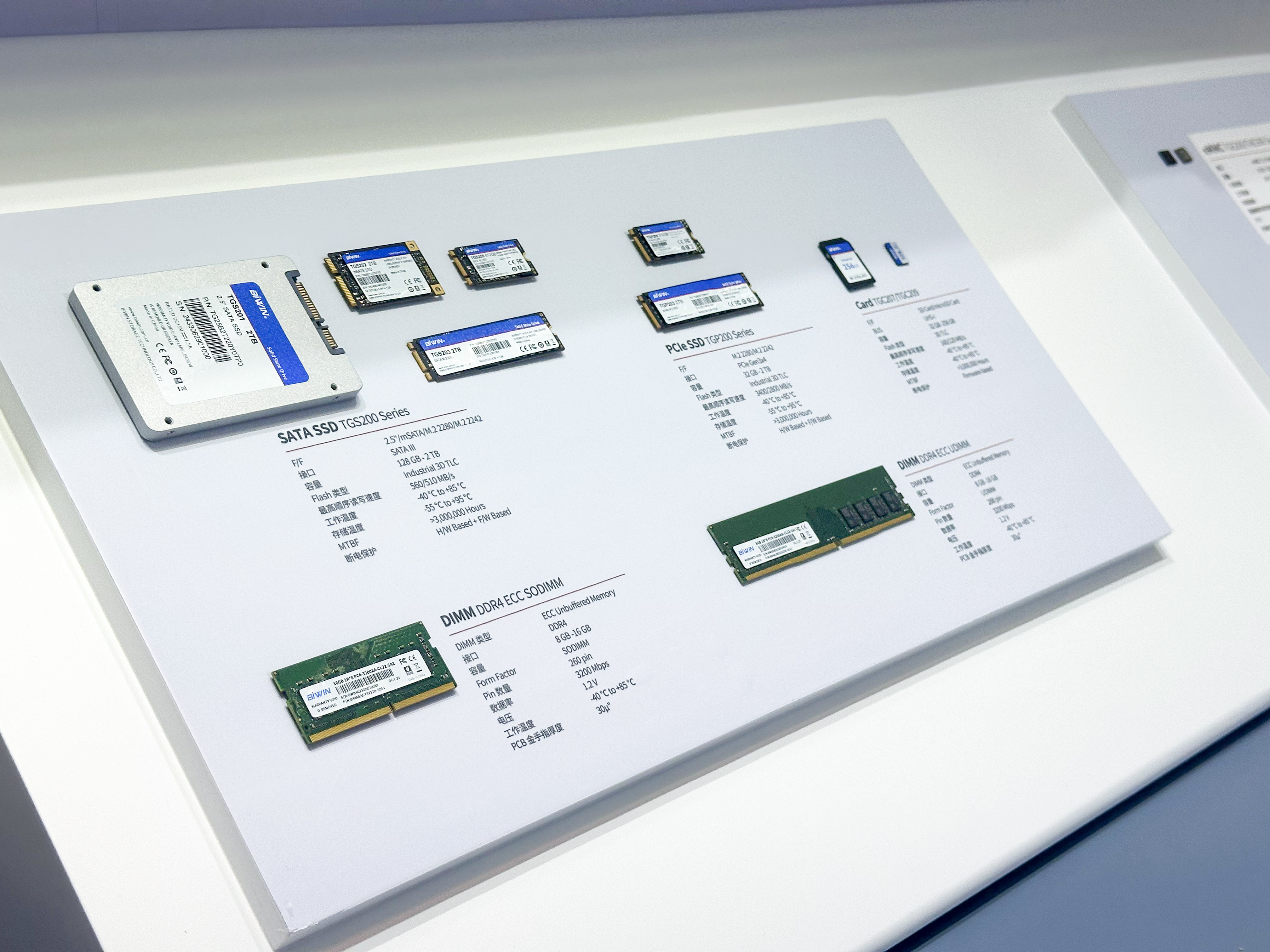

Building a Complete Industrial-Grade Product Portfolio

By leveraging its Integrated Solution and Manufacturing business model, BIWIN has built a self-sufficient technology ecosystem that covers core aspects of the storage industry through an integrated value chain spanning storage media research, controller design, firmware development, IC packaging and testing, and intelligent manufacturing. Through this model, BIWIN is able to conduct in-depth research tailored for specific demands from customers across different industries. By integrating innovation across product, technology, and service, it accurately addresses storage demands of vertical sectors such as electric power and industrial automation. This enables agile, end-to-end response from solution design to delivery, and supports joint development of scenario-based storage solutions with customers to create greater value.

(Benchmark Application Case Display Area)

Underpinned by the ISM model, BIWIN has established a full-spectrum industrial-grade storage matrix, encompassing industrial-grade SSDs, embedded storage, memory modules, and storage cards in a variety of form factors, interfaces, and dimensions, ensuring compatibility with a wide range of complex industrial scenarios. Engineered for industrial scenario features such as long-term uninterrupted operations, high frequency data transfers, and resilience in extreme environments, the product has achieved deep optimizations in both hardware and firmware. The use of corrosion-resistant industrial-grade PCBs and wide-temperature components ensures hardware reliability; self-developed technologies, backed by the strong firmware development team, including pSLC mode, intelligent power loss protection, bad block management, enhanced ECC, GC management, wear leveling, and runtime log preservation, help safeguard data integrity under harsh conditions such as vibration, extreme temperatures, and unexpected power loss.

In addition, all products have been adapted to industry mainstream SoC platforms to ensure broad compatibility. Backed by strong supply chain integration capabilities, the company is committed to providing customers with long-term, stable supply and offers fixed BOM services to ensure product consistency and reliability.

Conclusion

Guided by the unique requirements and standards of the smart grid sector, BIWIN places technological innovation at its core to develop fully self-controlled solutions that solve key storage challenges in the field. Beyond the energy industry, BIWIN’s in-house capabilities in solution development and packaging & testing allow for quick responses to niche industrial demands. By developing tailored products that closely align with customers’ real-world business scenarios, BIWIN delivers added value to support the intelligent operation of various industries.